Visualized Management on Data

———

Visualized Management on Data

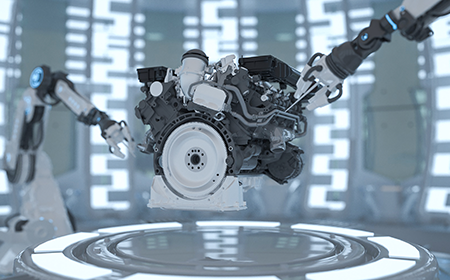

In a real-time and dynamic way, production state, consumption state of raw materials, operation state of devices, productivity state can be reflected in the process of production and normal operation parameters can be set. Abnormal situations in the operation process is prompted in the way of visualized alarming, data-driven basis is provided for Digital Twin factories. Real-time analysis and application of perceived data is realized.

Intelligent Operation of Factories

———

Intelligent Operation of Factories

Targeted production and digitalized operation are conducted based on total-factor management on data-driven factories to realize smart management, to perceive operation state of factories in real time, to construct overall-perception Digital Twin factories, which provides an overall scenario for the following intelligent operation as well as guidance for intelligent management on decision making to realize smart operation.

Digitalized Operation

JIC Digital Twin Platform creates a real-time, accurate and efficient enterprise-level integrated platform for operation and management of smart bus for the Bus Group, to realize monitoring on operation state of buses and visualized shceduling. It also provides clients with new solution to smart operation & maintenance and management of buses.

Targeted Production

JIC can provide cloud storage, big data processing, edge computing, smart recognition algorithm, console control, system docking and other solutions about software and hardware to facilitate the management on smart protection and defense.

Smart Control

Via online measurement on data, acquisition on historical operation data of electricity system, integrated with electricity, computer, communication, climate, economy and so on, JIC Digital Twin constructs digital twin of smart electricity grid to reflect process of product lifecycle.

Massive Industrial Mechanism Model Base

———

Massive Industrial Mechanism Model Base

Millions of industrial base models, digital models, control models have been accumulated in the Digital Twin Platform to transform Invisible Data into Visible Operating Instruction, to promote the Scientific Decision Making and Autonomous System in the whole production process of enterprises, to simulate on production process of factories by utilizing models and to generate optimal production solution quickly.

Analysis on Data Assets

———

Analysis on Data Assets

Massive production datum are accumulated in Digital Twin Factory, including all-round datum such as workers, machines, materials, rules, environment, ERP and so on. Based on data-driven optimization and innovation of businesses, confined factors on production can be eliminated, and general production efficiency as well as management level can be improved. The assets can be truely realized and competiveness of enterprises can be raised.

Wastes Elimination

Based on data-driven innovation of businesses, brand new management modes and lean management concept can be brought for managers of businesses to eliminate all kinds of wastes in the process of production.

Data Assets

Data is regarded as a kind of asset, and the value of data can be explored by making full use of the algorithm of big data. Predictive maintenance on devices can be conducted according to data model to reduce the downtime.

Globally Digitalized Management on Equipment Assets

———

Equipment Asset Management

Digital Twin Factory constructs virtual models of factories to realize the digitalized management on all assets. Assets can be sorted and be conducted unified online management to eliminate discrete management on traditional equipment assets, to raise the efficiency, transparency and utilization rate of asset management.

Device Management

Management on Materials

Management on Inventory

Clear Responsibility Management

Management on Energy Consumption

Digital Twin Factory

Digital Twin Factory